Elbphilharmonie, Hamburg

|

Architect:

|

Herzog & De Meuron |

|---|---|

|

Structural engineers:

|

Schnetzer Puskas International AG |

|

Client:

|

Elbphilharmonie Bau KG |

|

Our customer:

|

HOCHTIEF |

|

Construction period:

|

2007-2016 |

This magnificent building has been much maligned and portrayed as a failure – quite unfairly in our view.

In fact, we believe that it will come to set the gold standard for European architecture for years to come!

more

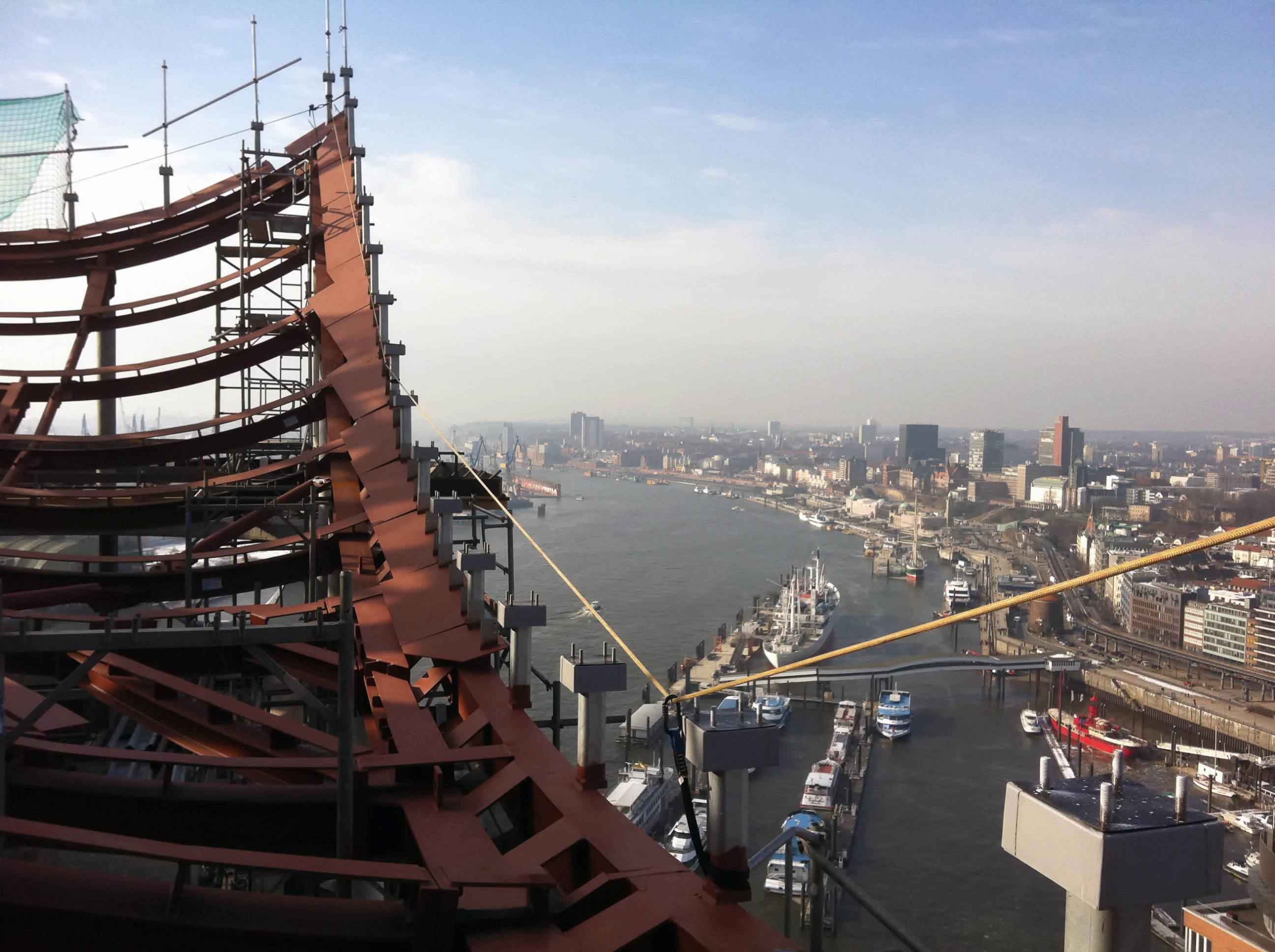

Public perception in Hamburg has not even begun to grasp the full potential of this building. Take for example the wonderful play of colours on the facade. For just €1.50 you can hop on a ferry and enjoy the view from the water! Choose the circular route which runs from Landungsbrücken to Arningstraße and Elbphilharmonie and back, and you don’t even have to get off the boat. This trip is particularly worthwhile in the afternoon when the sun is low in the sky, or after heavy rain (a frequent occurrence in Hamburg) – it’s a fantastic photo opportunity!

We contributed in no small way to the success of this project and have the highest regard for all the companies involved in the construction (Gartner, Wittenauer, Peuckert, Lenz und Mundt, Teupe, Nietiedt, etc.) and especially HOCHTIEF and the architects Herzog & de Meuron.

spannverbund supplied and installed the steelwork (including the technical design work) for the following components:

- building roof (spatially curved steel structure with an area of 5,600 m2), including profiled steel sheeting (angle of inclination to 55°)

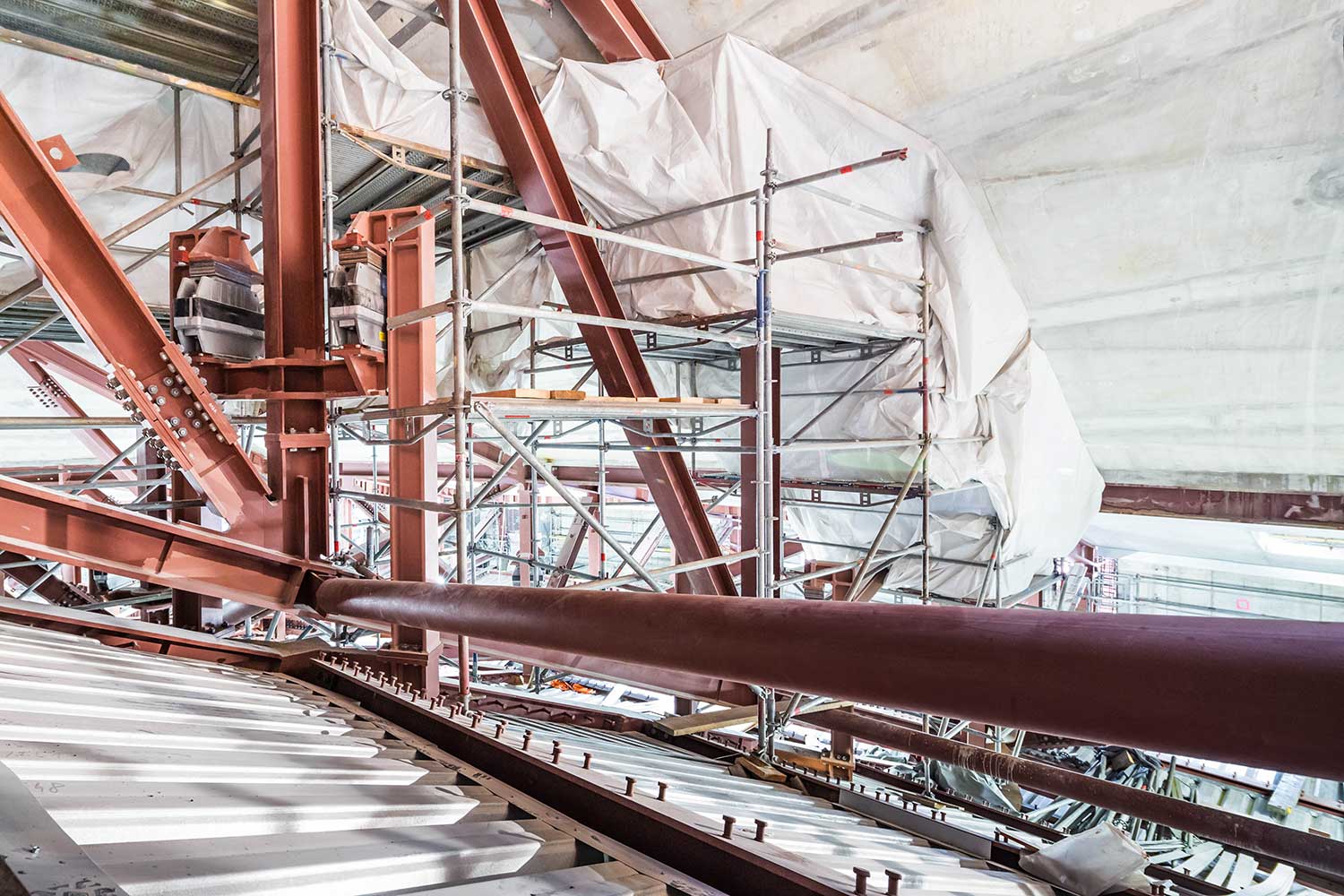

- concert hall roof trusses (spatial truss with a span of 55 x 50 m and a height of 2 to 20 m)

- inner shell (a composite floor slab, including 2,280 m² of profiled steel sheeting, attached to the hall roof trusses by springs

- mechanical floors between the building roof and the hall roof

- maintenance passages in the space between the inner shell and the hall roof

- an 18 to 38 m high steel platform in the Grand Concert Hall for assembling the roof of the concert hall, including its subsequent dismantling

- formwork elements for the production of Y-shaped branches for high-strength concrete columns

(In this list of about 2000 tonnes of steel components, no two parts are like; each item is unique.)

- facade edge beams and edge trusses

- steel structure for the reflector in the Grand Concert Hall

- slender, inclined composite columns at the edge of the building (two to three columns converge at the base support)

- heavily loaded composite columns (Nd = 26,400 kN) inside the building

- heavy cast-in elements with a load capacity of up to 23,000 kN for load introduction into the concrete columns

- temporary elevated mounting platforms for hollow-core slabs

- various small cast-in elements for stairs, etc.